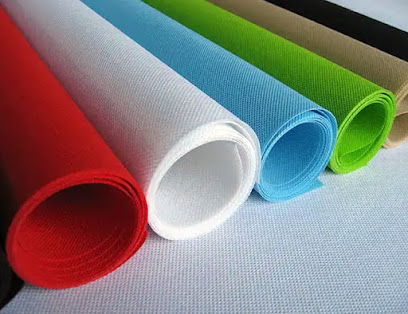

Non-Woven Fabric Explained: Manufacturing, Types, and Applications

Non-woven fabrics have become essential across industries due to their versatility, durability, and cost-effectiveness. From healthcare to automotive, non-woven materials provide high-performance solutions in areas where traditional textiles may not be as effective. Jhanji Textiles specializes in producing high-quality non-woven fabrics, offering solutions that cater to a wide range of applications. In this article, we explore the manufacturing process, types, and key applications of non-woven fabrics.

Manufacturing of Non-Woven Fabrics

Non-woven fabrics are manufactured without weaving or knitting, making them structurally different from traditional woven textiles. Instead, non-woven fabrics are made by bonding fibers together through various processes, including chemical, thermal, or mechanical bonding. The manufacturing techniques can be broadly divided into three primary methods:

Spunbonding: In this process, polymer granules are melted and extruded through spinnerets to create fine filaments, which are laid randomly to form a web. The web is then bonded to create a strong, durable fabric. Spunbond non-wovens are commonly used in applications like medical masks and agricultural fabrics.

Meltblowing: Meltblown non-woven fabrics are made by blowing hot air through polymer melt, creating ultra-fine fibers that are laid into a web. Meltblown fabrics are known for their excellent filtration properties, making them ideal for medical and industrial filtration applications.

Needle-Punching: This method mechanically entangles fibers using barbed needles to form a cohesive fabric. Needle-punched non-wovens are highly durable and are widely used in geotextiles, automotive carpeting, and insulation materials.

Types of Non-Woven Fabrics

The diverse types of non-woven fabrics are suited to various applications due to their unique properties:

Spunbond Non-Woven Fabrics: Known for their strength, durability, and cost-effectiveness, spunbond non-wovens are commonly used in applications where high tensile strength is required, such as in disposable hygiene products, medical supplies, and protective clothing.

Meltblown Non-Woven Fabrics: Meltblown fabrics are characterized by their fine fibers and superior filtration abilities. They are extensively used in air and liquid filtration systems, face masks, and insulation due to their ability to trap particles effectively.

Needle-Punched Non-Woven Fabrics: These fabrics are dense and resilient, making them ideal for heavy-duty applications. Needle-punched non-wovens are widely used in automotive interiors, geotextiles, and construction materials for their durability and sound-absorbing qualities.

Hydroentangled (Spunlace) Non-Woven Fabrics: In this process, high-pressure water jets entangle fibers to form a soft and absorbent fabric. Spunlace non-wovens are commonly used in personal care products, wipes, and medical dressings due to their gentle, absorbent nature.

Applications of Non-Woven Fabrics

Non-woven fabrics offer solutions for a wide range of industries:

Healthcare: Non-woven fabrics are critical in healthcare for products such as surgical gowns, masks, and disposable hospital linens. Their ability to provide sterility, absorbency, and protection makes them invaluable in medical settings.

Automotive: In the automotive industry, non-wovens are used for cabin air filters, seat linings, sound insulation, and carpets. Their lightweight, durable nature makes them ideal for improving vehicle comfort and efficiency.

Agriculture: Non-woven fabrics are increasingly used in agriculture as crop covers and weed barriers. Their breathable nature allows air, sunlight, and water to reach plants while protecting crops from pests and harsh weather.

Filtration: The filtration industry relies heavily on non-wovens for air and liquid filtration. Due to their superior particle retention, meltblown non-wovens are commonly used in HVAC systems, water purifiers, and industrial filtration systems.

Construction and Geotextiles: Non-woven geotextiles are widely used in construction for erosion control, drainage, and soil stabilization. Their strength and resilience make them suitable for reinforcing road foundations and stabilizing slopes.

Conclusion

Non-woven fabrics have revolutionized multiple industries with their adaptability, durability, and performance. From healthcare and automotive to agriculture and construction, non-wovens provide specialized solutions that cater to the unique requirements of each sector. Jhanji Textiles is dedicated to manufacturing high-quality non-woven fabrics that meet the diverse needs of modern industries, making us a trusted partner for businesses seeking reliable, innovative solutions.

Comments

Post a Comment